Agricultural Value and Supply Chains Optimization

- 01

- Jun

Patisiwe Green Garden, Gokwe, Zimbabwe

Food loss and waste is currently an issue that is occurring all over the world while others are starving because of a lack of enough food, the climate is also affected badly.

Postharvest technology challenge for African Agri producers

A report by MIT suggested that the world produces enough food however about 40 to 60% of food produced, mostly by developing nations, is lost or wasted due to poor postharvest techniques. As smallholder farmers produce vegetables and consumers deserve quality, it is imperative to secure and safely organize the handling of vegetables and other foods.

According to the UN FAO 30% of food wasted globally across the supply chain, contributes 8% of the total global gas emissions. If food waste were a country, it would come third after the United States and China in terms of impact on global warming. Growing food that goes to waste ends up using a significant amount of freshwater, fertilizers, pesticides, farmlands, and even dump sites, Ben Simon, Co-founder and CEO of Imperfect Foods refers to this as “When we waste food, we are not just wasting food…also, we are wasting all the resources that went into its production.”. More than 70 billion tons of greenhouse gases, in this regard Methane Gas, could be prevented from being released into the atmosphere. A pound of methane gas traps heats about 21 times more than carbon dioxide gas (also a greenhouse gas). Most food waste worldwide occurs when food is left in the field, however, food is not wasted the same way in every part of the world. In high and medium-income countries, 40% of food waste occurs in markets and by consumers. Contrary to low-income countries or developing nations, food is rarely wasted by households, instead, 40% is lost during the post-harvest and processing stages usually due to lack/ poor infrastructure and inefficient or fewer storage facilities and technology. This defines the problem along the supply chain.

The break in the food supply chain (A Case of Ghana)

As defined, Ghana can be classified as a low-income or developing country where a significant quantity of about 30-40% of food is wasted at post-harvest levels, inadequate and inefficient facilities to support post-harvest losses, and lack of market access are crucial. In the same way, the local market centers have challenges handling and storing vegetables which makes available low-quality vegetables to consumers.

Out of the 70% of the domestic production of foods (vegetables) in Ghana and distributed across the markets locally, the problem of post-harvest losses which affects the quality and marketability of vegetables by smallholder farmers reduces the value of their produce. They are exploited by middlemen, and find their roots in the lack of storage (and logistics) facilities as imports soar to about USD 2B+ annually and are significantly a factor in the high inflation rate of the country.

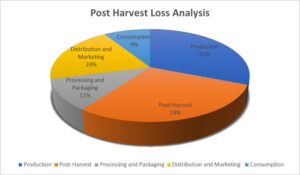

Considering this, the processor value chain of agriculture especially horticultural produce (fruits and vegetables) is highly under pressure. Like Ghana, just like most developing countries are facing equally similar challenges. A Figure of post-harvest loss Analysis .

To breakdown further:

- Production (31%) is faced with challenges like;

Poor quality starting materials and inputs.

Poor practices and best agricultural procedures.

Very limited access to low-cost technologies.

Lack of farm infrastructure

Poor harvesting techniques and logistics.

- Post-Harvest contributes (29%) to the challenges by

Poor practices of on-farm storage and handling(logistics). E.g., harvesting cucumbers into polythene sacks for transport to markets.

Distress sales. Failure to do market-first approach production.

Lack of market linkages.

- Processing and Packaging (11%)

Poor linkages to farm

Insufficient local processing and value addition capacity

- Distribution and Marketing (20%)

Limited transport and logistical infrastructure for perishable produces.

Multiple middlemen, agents, and traders.

Less technology-backed systems to support the free flow of produce.

Less structured and coordinated supply chain points.

- Consumption (9%)

Limited access to the export market.

A closer look at this breakdown, from points 2, 3, and 4 are classified together as post-harvest activities that is through their food gets to consumers therefore the accumulated percentage is 60% (29+11+20).

To conclude, This is actually a break in the supply chain rendering most agribusinesses not profitable. It is critical to note that infrastructure costs for very basic machinery or setups are quite higher due to less subsidy or catalytic capital to acquire these units. There are some ways like low-cost setups of aggregation centers with packhouses and cold storages to hold produce from spoilage like the ZECC (Zero Evaporative Cooling Chamber) etc.

In my view, an overhaul of the value chain plus the establishment of a solid supply chain infrastructure powered by data (software) is essential to be considered for optimization. SmithField (startup) is an agribusiness utilizing technology like USSD and other homegrown software in relation to supply chain management, logistics, and distribution and retail services for the Food and Agricultural sector. Providing First mile solutions purposely supporting the mitigation efforts on post-harvest losses and enhanced nutrition is essential to our existence as a business. Though constrained to finance, we are still focused on achieving this goal and scale along with the West African and African sub-region. We aim to optimize the supply chain system backed by technology and data.

EuroAfri Link is a member of the Africa chapter advocate at the EU Tech Chamber (EUTECH), with a strong focus on linking technology in food & Agri value chains from Europe to Africa, to promote productivity and food quality. In that case, a lot of the food will be saved or transformed into usable products like feed thanks to tech.

Author: Stanley Smith– Acquah, BSc. FSSC 22000

A multitasking individual who specializes in administrative solutions like business and marketing research and management, project management, technology, product development and sustainability in organizations.

All these specializations have been deployed in the agricultural development space. Worked on agricultural contracts and freelance with industry players locally and foreign.

Stanley is a member of the Association of Certified Chartered Economists of the American Association of Financial Management- the USA specializing in Industrial Economics. He holds a degree in Economics and Business Administration, Advanced Certificate in Logistics and Transport Management, and certified Food Safety internal auditor (FSSC 22000) amongst other professional certifications.

Currently founder of SmithField Agribusiness LLC dealing with the restoration of decent food systems and security in the country focusing on supply chain, logistics, and distribution. Looking to upscale through the West Africa subregion. Stanley is an alumnus of YALI West Africa RLC and an award recipient as one of the outstanding leaders during his cohort. Contact Stanley at ekowsmith3@gmail.com +233208000035/ +233247564347